Language

Language

Language

Language

Production capacity: ≤120m3/h

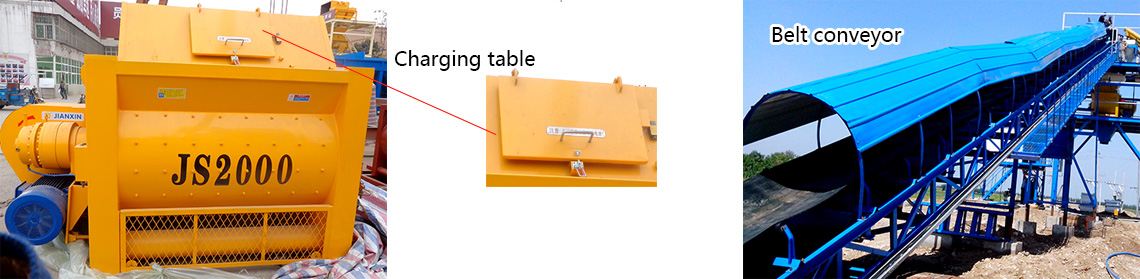

Mixer model: JS2000

Discharge capacity: 2000L

JS2000 concrete mixer is a kind of machinery which uses pressure to transport concrete along the pipeline continuously. It is composed of pump body and conveying pipe. It is mainly divided into gate valve concrete pump and S valve concrete pump, but according to the structure can be divided into Piston type, squeeze type, hydraulic diaphragm type, the pump body is mounted on the chassis of the car, and then equipped with retractable or inflecting booms, it forms a pump truck, which is mainly used in construction of houses, bridges and tunnels.

JS2000 concrete mixer Mixing system

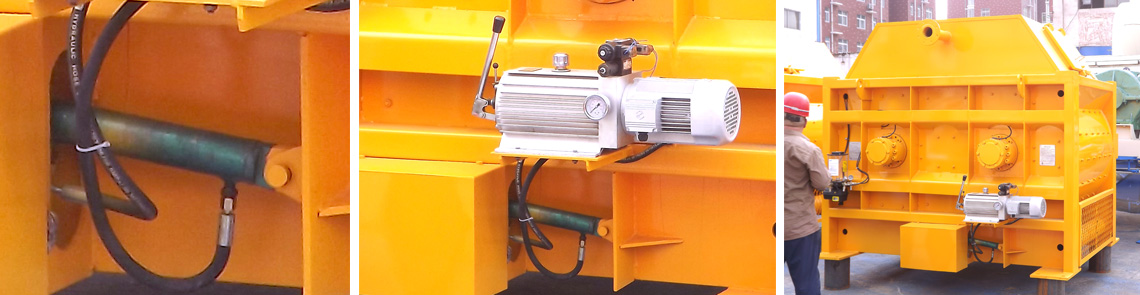

The mixing system of JS2000 concrete mixer is composed of electric motor, pulley, reducer, open gear, mixing drum stirring device, oil supply device and so on. The motor of the JS2000 concrete mixer is directly connected to the cycloidal pin reducer. By means of the split gears, the two output shafts of the reducer drive respectively the horizontally arranged agitating shaft to reverse the rotation at the same speed.

JS2000 concrete mixer Feeding system

The feeding system of JS2000 concrete mixer is composed of hoisting mechanism, loading rack, hopper feeding nozzle and so on. A limit switch is installed on the loading frame, and the upper limit has two limit switches, which respectively paly a role in raising the limit position and safety protection of the hopper with rise of the hopper. The upper part of the loading rack is foldable.

JS2000 concrete mixer Discharging system

| Project | Discharge capacity | Feed capacity | Theoretical productivity | Maximum granule of aggregate (Lithotripsy/Pebble) | Working cycle time | Power of stirred motor | Speed of stirred motor | Shape size (Length, width and height) |

| JS2000 | 2000L | 3200L | ≤120m³/h | ≤80/100 | 60(S) | 2×37KW | 24.5(r/min) | 3500×2400 ×2125 |

| Project | Discharge capacity(L) | Feed capacity(L) | Theoretical productivity(m³/h) |

| JS2000 | 2000L | 3200L | ≤120m³/h |

Tel:0086-18437125333/0086-371-86598800

Tel:0086-18437125333/0086-371-86598800

Fax:+86-371-86599393

Fax:+86-371-86599393

E-mail: jianxin@zzjxcorp.com

E-mail: jianxin@zzjxcorp.com

Address:West 200m of Guangwu Road and G310 National Way intersection, Xingyang-Zhengzhou City, Henan Province, 450100 China

Address:West 200m of Guangwu Road and G310 National Way intersection, Xingyang-Zhengzhou City, Henan Province, 450100 China

WeChat:18437125333